Made In Canada

Made In Canada

BEHLEN Steel Buildings ARTSPAN Insulated Metal Panels

BEHLEN Industries LP offers the ARTSPAN Insulated Metal Panel available for purchase with any BEHLEN Rigid Frame Steel Building System.

The ARTSPAN IMPs are available in a variety of profiles including Skyline Roof, Horizon Wall, and Leading Edge Wall panels. They can be installed as exterior and interior vertical walls and high-performance roofs; including cold storage applications. They are well suited for agricultural, industrial, commercial, recreational, and intuitional projects of all sizes and complexities.

The installation of insulated metal panels is quick and easy, allowing the buildings to be completely enclosed in a fraction of the time compared to conventional wall assemblies. The superior thermal values make increasing thermal performance across climate zones easy to achieve for both walls and roofs.

Horizon Wall Panels: General Information

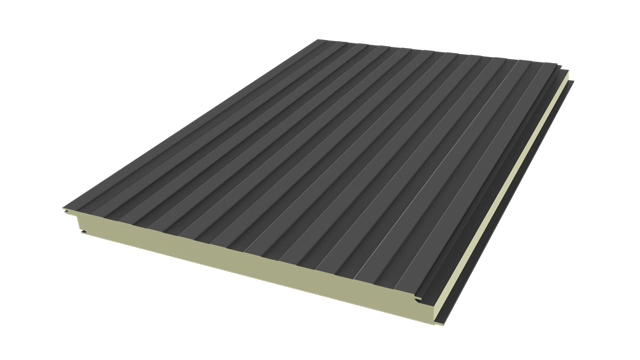

Horizon Wall - Smooth Panel

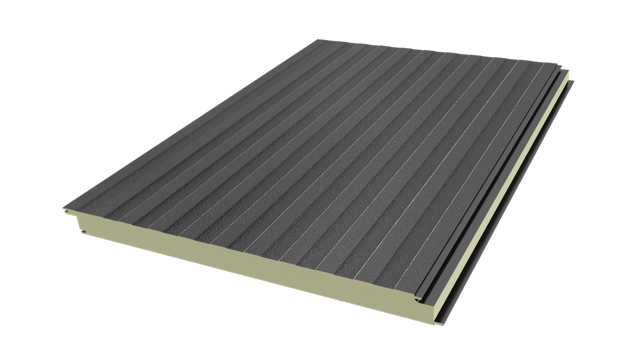

Horizon Wall - Embossed Panel

Horizon Wall – Mesa Smooth panels are produced with a standard Mesa profiled smooth steel face. These panels are an economical option for industrial and commercial walls, with added strength.

- Coverage Width: 42” (1067mm).

- Panel Lengths: 8’ to 52’ (2438mm to 15850mm).

- Exterior Face: 22ga, 24ga, or 26ga Mesa Smooth galvanized G-90 (Z275) pre painted steel.

- Interior Face: 22ga, 24ga, or 26ga Mesa profile in Smooth or Light Embossed finish galvanized G-90 (Z275) pre painted steel in Regal White. Other colour options may be available.

Horizon Wall – Mesa Light Embossed panels are produced with a standard Mesa profiled Light Embossed steel face. These panels are an economical option for industrial and commercial walls, with added strength from a double Mesa profile for long panel lengths.

- Coverage Width: 42” (1067mm).

- Panel Lengths: 8’ to 52’ (2438mm to 15850mm).

- Exterior Face: 22ga, 24ga, or 26ga Mesa Light Embossed galvanized G-90 (Z275) pre painted steel

- Interior Face: 22ga, 24ga, or 26ga Mesa profile in Smooth or Light Embossed finish galvanized G-90 (Z275) pre painted steel in Regal White. Other colour options are available.

Skyline Roof Panels: General Information

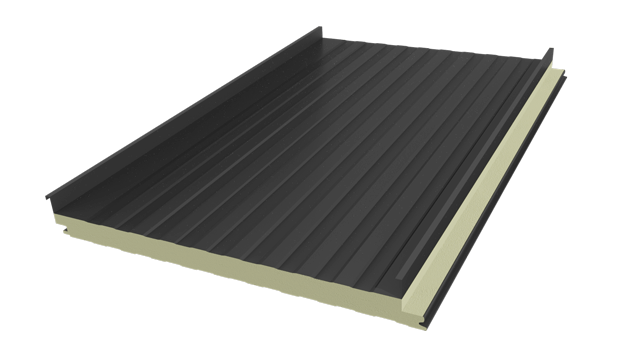

Skyline Roof Panel

Skyline Roof panels are produced with a standard Mesa profiled non-embossed smooth steel face. These roof panels are an economical option for industrial and commercial projects. The 2” Standing seam is mechanically folded and incorporates a hidden fastened clip.

- COVERAGE WIDTH: 42” (1067mm)

- PANEL LENGTHS: 10’ to 52’ (3048mm to 15850mm)

- EXTERIOR FACE: 22ga, 24ga, or 26ga Mesa Smooth galvanized G-90 (Z275) pre painted steel

- INTERIOR FACE: 22ga, 24ga, or 26ga Mesa profile in Smooth or Light Embossed finish galvanized G-90 (Z275) pre painted steel in Regal White. Other colour options are available.

Edge Wall Panels: General Information

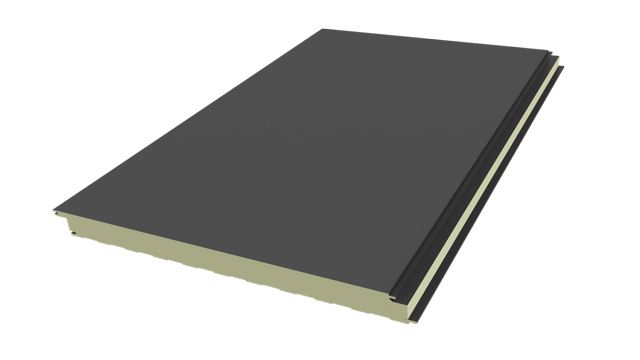

Edge Wall - Smooth Panel

Edge Wall - Light Embossed Panel

Leading Edge – Smooth panels are produced with a standard smooth steel face. This provides a flat, smooth face, adding a clean look to the exterior.

- COVERAGE WIDTH: 42” (1067mm)

- PANEL LENGTHS: 8’ TO 32’ (2438mm to 9754mm)

- EXTERIOR FACE: 22ga Flat Smooth galvanized G-90 (Z275) pre painted steel

- INTERIOR FACE: 22ga, 24ga, or 26ga Mesa profile in Smooth or Light Embossed finish galvanized G-90 (Z275) pre painted steel in Regal White. Other colour options may be available.

Leading Edge Wall – Light Embossed panels are produced with a standard light embossed flat steel face. This provides added subtle visual texture to a flat panel.

- COVERAGE WIDTH: 42” (1067mm)

- PANEL LENGTHS: 8’ TO 32’ (2438mm to 9754mm)

- EXTERIOR FACE: 22ga Flat Light Embossed galvanized G-90 (Z275) pre painted steel

- INTERIOR FACE: 22ga, 24ga, or 26ga Mesa profile in Smooth or Light Embossed galvanized G-90 (Z275) pre painted steel in Regal White. Other colour options are available.

ARTSPAN Skyline Roof Panel, Horizon Wall Panel, and Leading Edge Wall Panel profiles are all available in several thicknesses with the associated thermal value shown in this chart.

| THICKNESS | 2” | 3” | 4” | 5” | 6” |

|---|---|---|---|---|---|

| R-VALUE* | 16.67 | 25 | 33.33 | 41.67 | 50 |

| U-FACTOR | 0.060 | 0.040 | 0.030 | 0.024 | 0.020 |

| U-VALUE SI (W/m²xK)* | 0.341 | 0.227 | 0.170 | 0.136 | 0.114 |

Test based on ASTM C1363 with 40F (4.4C) mean temp with a temp differential of 58F (14C).

- Metallic colours are batch sensitive and directional in nature.

- Special order in 22ga. Colour selection may affect maximum panel lengths. Please contact for delivery times and additional information.

Standard Colours

- Ash Grey

- Charcoal

- Old Town Grey

- Old Zinc Grey

- Regal White

- Sierra Tan

- Weathered Copper

Premium Colours

- Parchment

- Champagne Metallic

- Mocha

- Bronze

- Dark Bronze

- Copper Penny

- Terra Cotta

- Colonial Red

- Retro Red

- Hemlock Green

- Forest Green

- Hartford Green

- Black

- Silver Metallic

- Twilight Blue

- Regal Blue

- Weathered Zinc

- Slate Grey

ARTSPAN roof and wall panels have been tested and evaluated by an independent third-part laboratory and testing certification. All panels are inspected and certified by our manufacturer; QAI File B1113.

| Standard | Description | Results |

|---|---|---|

| CAN/ULC S101 | Standard Methods of Fire Endurance Tests of Building Construction and Materials | 15-minute stay in place |

| CAN/ULC S102 | Standard Method of Test for Surface Burning Characteristics of Building Materials and Assemblies | Flame Spread < 25, Smoke Development < 200 |

| CAN/ULC S126 | Standard Method of Test for Fire Spread Under Roof-Deck Assemblies | Complies |

| CAN/ULC S127 | Standard Corner Wall Method of Test for Flammability Characteristics of Non-Melting Foam Plastic Building Materials | Flame Spread < 350 foam core w/o steel skin |

| CAN/ULC S138 | Standard Method of Test for Fire Growth of Insulated Building Metal Panels in a Full-Scale Room Configuration | Complies |

| ASTM E84 | Standard Test Method for Surface Burning Characteristics of Building Materials | Flame Spread < 25, Smoke Development < 200 |

| NFPA 286 | Standard Methods of Fire Tests for Evaluating Contribution for Wall and Ceiling Interior Finish to Room Fire Growth | Complies |

| ASTM E72 | Standard Test Methods of Conducting Strength Tests of Panels for Building Construction | See Load Charts for load/span and deflection tables |

| ASTM E1592 | Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference | See Load Charts |

| ASTM E1646 | Standard Test Method for Water Penetration of Exterior Metal Roof Panel Systems | No water penetration at 20 psf pressure differential |

| ASTM E1680 | Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems | 0.02 L/(s.m2) at 75 Pa (0.004 cfm/ft2 at 1.57 psf) |

| ASTM E283 | Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen | 0.02 L/(s.m2) at 75 Pa (0.004 cfm/ft2 at 1.57 psf) |

| ASTM E331 | Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference | No water penetration at 20 psf pressure differential |

| ASTM C518 | Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus | K-Factor of 0.136 BTU.in/hr.ft2. °F at 75°F |

| ASTM C1363 | Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus | K-Factor of 0.12 BTU.in/ hr.ft2. °F at 39°F |

*Standards are tested and valid for all IMP Product lines, including Edge Wall, Horizon Wall, and Skyline Roof panels. 2020

- PRODUCT: Insulated Wall Panel

- PROFILE: Mesa or Smooth

- SERIES: Edge, Horizon

- GAUGE: 26ga or heavier

- FINISHED: Embossed or Smooth

| Panel Thickness | Design Criteria | 4′ Allowable Loads (PSF) | 5′ Allowable Loads (PSF) | 6′ Allowable Loads (PSF) | 7′ Allowable Loads (PSF) | 8′ Allowable Loads (PSF) | 9′ Allowable Loads (PSF) | 10′ Allowable Loads (PSF) | 11′ Allowable Loads (PSF) | 12′ Allowable Loads (PSF) | 13′ Allowable Loads (PSF) | 14′ Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2″ Thick (See Table Note #3) |

Bending/Shear | 93 | 59 | 41 | 30 | 23 | 18 | 15 | 12 | 10 | ||

| 2″ Thick | Deflection (L/180) | 47 | 41 | 33 | 27 | 22 | 19 | 16 | 14 | 12 | ||

| 2″ Thick | Connection | 42 | 35 | 33 | 26 | 22 | 19 | 16 | 15 | 13 | ||

| 3″ Thick | Bending/Shear | 126 | 101 | 84 | 68 | 52 | 41 | 33 | 27 | 23 | ||

| 3″ Thick | Deflection (L/180) | 94 | 77 | 68 | 58 | 34 | 32 | 29 | 19 | 17 | ||

| 3″ Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | ||

| 4″ Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 4″ Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 4″ Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 5″ Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 5″ Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 5″ Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 6″ Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 6″ Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 6″ Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

TABLE NOTES:

1) Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2) Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3) Connection strengths reflect a standard fastener pattern – with two (2) 1/4″ – 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately. 2″ wall panel utilize a flat clip. All other thicknesses utilize an angle clip.

4) Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5) Allowable loads assume a minimum bearing of 2″.

6) Thermal Effects were not considered in analysis.

7) The structural capacity of the supporting members were not considered.

8) Bending/Shear and Deflection for 5″ and 6″ panels based on 4″ capacity.

- PRODUCT: Insulated Roof Panel

- PROFILE: Mesa

- SERIES: Skyline

- GAUGE: 26ga or heavier

- FINISHED: Smooth

| Panel Thickness | Design Criteria | 2′ Allowable Loads (PSF) | 3′ Allowable Loads (PSF) | 4′ Allowable Loads (PSF) | 5′ Allowable Loads (PSF) | 6′ Allowable Loads (PSF) | 7′ Allowable Loads (PSF) | 8′ Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|

| 2″ Thick | Bending/Shear | 192 | 128 | 96 | 77 | 64 | 49 | 38 |

| 2″ Thick | Deflection (L/240) | 58 | 53 | 48 | 43 | 36 | 29 | 24 |

| 2″ Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 3″ Thick | Bending/Shear | 192 | 128 | 96 | 77 | 64 | 49 | 38 |

| 3″ Thick | Deflection (L/240) | 58 | 53 | 48 | 43 | 36 | 29 | 24 |

| 3″ Thick | Connection | 64 | 44 | 33 | 26 | 22 | 19 | 16 |

| 4″ Thick | Bending/Shear | 291 | 224 | 168 | 134 | 112 | 96 | 84 |

| 4″ Thick | Deflection (L/240) | 98 | 95 | 92 | 90 | 76 | 63 | 53 |

| 4″ Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 5″ Thick | Bending/Shear | 317 | 286 | 215 | 172 | 143 | 123 | 107 |

| 5″ Thick | Deflection (L/240) | 108 | 102 | 96 | 90 | 83 | 70 | 58 |

| 5″ Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

| 6″ Thick | Bending/Shear | 349 | 312 | 248 | 199 | 166 | 142 | 124 |

| 6″ Thick | Deflection (L/240) | 110 | 110 | 109 | 109 | 108 | 92 | 77 |

| 6″ Thick | Connection | 65 | 44 | 33 | 26 | 22 | 19 | 16 |

TABLE NOTES:

1. Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2. Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3. Connection strengths reflect a standard fastener pattern – with two (2) 1/4″ – 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately.

4. Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5. Allowable loads assume a minimum bearing of 2″.

6. Thermal Effects were not considered in analysis.

7. The structural capacity of the supporting members were not considered.

PANEL WEIGHTS (PSF)

| Panel Thickness (in.) |

Panel Width (in.) |

26/26 Steel Gauge (Facer/Liner) | 24/26 Steel Gauge (Facer/Liner) | 22/26 Steel Gauge (Facer/Liner) | 26/24 Steel Gauge (Facer/Liner) | 24/24 Steel Gauge (Facer/Liner) | 22/24 Steel Gauge (Facer/Liner) | 26/22 Steel Gauge (Facer/Liner) | 24/22 Steel Gauge (Facer/Liner) | 22/22 Steel Gauge (Facer/Liner) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 2.23 | 2.48 | 2.73 | 2.48 | 2.73 | 2.98 | 2.76 | 2.98 | 3.23 |

| 3 | 42 | 2.44 | 2.69 | 2.94 | 2.69 | 2.94 | 3.19 | 2.94 | 3.19 | 3.44 |

| 4 | 42 | 2.65 | 2.90 | 3.15 | 2.90 | 3.15 | 3.40 | 3.15 | 3.40 | 3.65 |

| 5 | 42 | 2.85 | 3.10 | 3.35 | 3.10 | 3.35 | 3.60 | 3.35 | 3.60 | 3.85 |

| 6 | 42 | 3.06 | 3.31 | 3.56 | 3.31 | 3.56 | 3.81 | 3.56 | 3.81 | 4.06 |

MAXIMUM PANEL LENGTHS BASED ON COLOUR (FT).

| Panel Thickness (in.) | Panel Width (in.) | Light Edge 22ga Wall* | Medium Edge 22ga Wall* | Dark Edge 22ga Wall* | Light Horizon 26ga/26ga Wall | Medium Horizon 26ga/26ga Wall | Dark Horizon 26ga/26ga Wall | Light Skyline 24ga/26ga Roof | Medium Skyline 24ga/26ga Roof | Dark Skyline 24ga/26ga Roof |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 25′ | 25′ | 20′ | 38′ | 25′ | 16′ | 47′ | 36′ | 24′ |

| 3 | 42 | 30′ | 30′ | 20′ | 45′ | 35′ | 25′ | 50′ | 38′ | 30′ |

| 4 | 42 | 30′ | 30′ | 25′ | 50′ | 38′ | 28′ | 52′ | 41′ | 32′ |

| 5 | 42 | 32′ | 30′ | 25′ | 52′ | 41′ | 30′ | 52′ | 44′ | 34′ |

| 6 | 42 | 32′ | 30′ | 25′ | 52′ | 44′ | 32′ | 52′ | 47′ | 36′ |

*Smooth or Embossed

Light = Regal White

Medium = Sierra Tan, Parchment, Silver Metallic

Dark = All others

Based on 5′ support spacing for walls & 4′ support spacing for roofs

*Smooth or Embossed

Subject to change without notice. Please refer to our website, www.artspaninc.com for current information.

- ARTSPAN IMP Product Guide

- ARTSPAN IMP Wall Standard Details

- ARTSPAN IMP Roof Standard Details

- ARTSPAN Horizon Wall Data Sheet

- ARTSPAN Leading Edge Data Sheet

- ARTSPAN Skyline Roof Data Sheet

- ARTSPAN Horizon Wall Guide Specifications

- ARTSPAN Leading Edge Wall Guide Specifications

- ARTSPAN Skyline Roof Guide Specifications